When Digital Twins Start Predicting the Future Instead of Mirroring Reality

- Digital twins are entering a new phase where they don’t just reflect reality but predict it, merging AI, simulation, and data to shape how industries plan, build, and operate.

- As these systems gain foresight, they promise greater efficiency and safety across sectors while demanding new standards for data quality, interoperability, and ethical use.

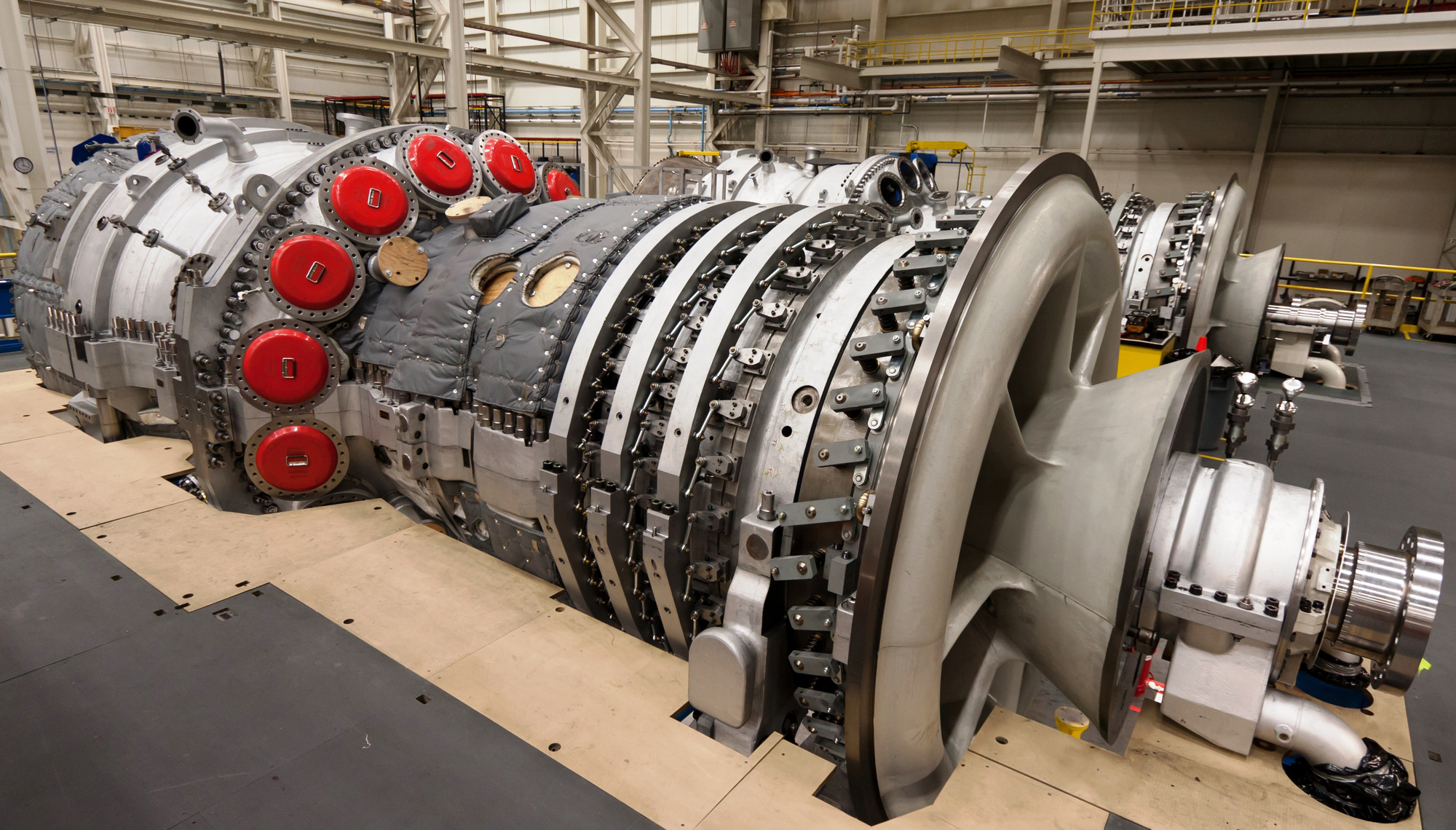

Picture this. A monitor has lit up in a quiet control room that is linked to a virtual model, or digital twin, of a turbine, which is identical in every detail to the real one located miles away. This virtual model has detected a fault that has not yet appeared on the physical machine. Before the physical machine even gets the chance to experience the fault, engineers make adjustments to it, and the problem never occurs. In this scenario, the digital twin has done more than reflect a reality soon to happen; it has predicted it.

For decades, digital twins have played a role in documenting past events. They mirror engines, factories, and systems in real-time, serving as both decision-making tools and precise record-keepers. However, according to McKinsey and Company, these systems are now learning to anticipate outcomes before they unfold, thanks to data modeling, simulation, and machine learning.

However, the shift reaches far beyond engineering, and as Siemens puts it, digital twins can "simulate, predict, and optimize" before a physical prototype is ever built. In practice, this capability is reshaping entire sectors. This means that digital twins are revolutionizing industries from manufacturing and healthcare to urban planning. For example, virtual replicas enable factories to schedule maintenance before a failure occurs, energy companies to forecast output and prevent blackouts, and cities and hospitals to test scenarios that previously required guesswork.

To put it simply, industries that rely on digital twins can utilize these systems to plan with foresight rather than hindsight. Digital twins are now more than ever transitioning from mirroring to predicting.

From Reflection to Foresight

Although the concept of digital twins was introduced in 2002 by Michael Grieves at a conference for the Society of Manufacturing Engineers, the foundational ideas behind digital twins have existed since the 1960s.

One of the first examples of digital twins, according to Siemens, was created during this era. NASA engineers synchronized a simulator on Earth with a damaged spacecraft during the Apollo 13 mission to test rescue maneuvers. However, it wasn't until decades later that NASA formalized the concept. They used a live model that continuously ingests data from a physical counterpart, allowing for 'what-if' experiments.

Like NASA in its early days, most industries initially used digital twins to represent the present in a straightforward manner, but the next generation of this technology far surpasses its original use cases. Digital twins are now merging physics-based modeling with historical and real-time data to forecast what will happen when conditions change. Siemens, a prominent voice in this space, refers to this as a 'time-machine' approach. One can replay the past, mirror the present, and model the future.

In the age of AI, it is no surprise that the technology is developing at near-alarming rates. This is evidenced by the rapid evolution of digital twins, now occurring at a faster and greater level of accuracy. According to McKinsey & Company insights, generative models now have the power to simulate millions of outcomes across parameters such as power, stress, or material consumption, enabling organizations to predict not only what will happen but also why it will occur.

It is the convergence of AI, simulation, and physics that enables digital twins to function as a predictive laboratory rather than a passive dashboard. Considering this approach is becoming widely adopted across industries, it's expected that the global digital twin market will expand by nearly 60% annually. Quantifiably based on Fortune Business Insights, this means it could reach a market value of about $80 billion in the next few years.

The Factory That Builds the Future

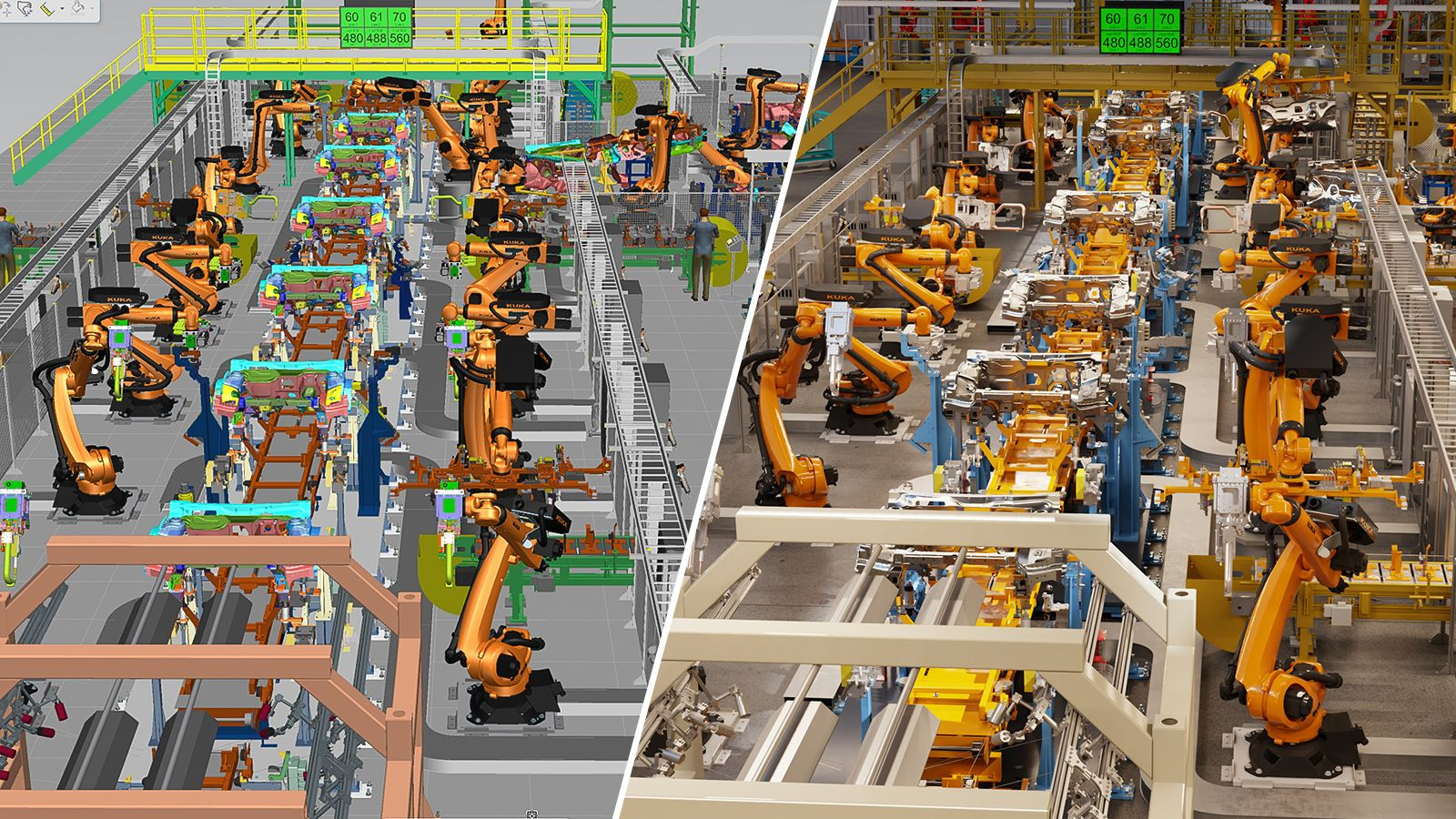

The manufacturing industry has become a proving ground for predictive modeling and the capabilities of digital twins. A prime example is BMW's plant in Debrecen, Hungary. At this plant, the entire facility was designed and tested in a wholly virtual ‘digital twin’ environment before BMW began construction, according to a report by Fast Company.

BMW collaborated with NVIDIA to create a 3D model of the factory, simulating every motion on the line and providing BMW with a comprehensive view of whether its facility would be effective. Rev Lebaredian, NVIDIA's vice president of simulation technology, told Fast Company: "They don't actually get to see whether their factory will work until they've built it." But: "by testing it digitally, they can detect thousands of problems before laying down one brick".

Source: YouTube / NVIDIA

Virtual factories aside, digital predictive twins can now also oversee the physical operations on the factory floor. According to GE Vernova, more companies are pairing machines with digital counterparts that are fed by sensors to learn operating patterns. This means that when something like a bearing begins to move differently than it otherwise should, the digital twin can flag this behavior long before a human set of eyes would notice. This flag alerts floor operators of potential issues before they happen so that something can be done about them.

Additionally, there are significant cost savings. As stated by GE Vernova, which houses a library of industrial digital twins worldwide, customers have saved $1.6 billion in repair costs and downtime. This is primarily thanks to the library's ability to analyze live data to forecast failures before they happen, and companies then having the power to act on these early warnings.

Essentially, production at manufacturing facilities no longer depends solely on reaction, as a factory itself can become a system that learns, tests, and anticipates.

Power That Plans Ahead

In the energy sector, prediction is becoming an integral part of infrastructure as digital twins help provide key insights into the complexities of energy networks, corroborated by ‘What is digital-twin technology?’ by McKinsey & Company. This foresight offered by digital twins often means the difference between stability and crisis in this sector.

A key example of how digital twins are reshaping the energy industry is the US Department of Energy's decision to fund research on a national 'digital twin of the grid.' These strategic research initiatives will enable utility departments to anticipate a range of potential issues. These issues can include cyberattacks, transformer wear, and power outages.

Additionally, in the UK, the National Grid ESO is developing a network twin to accelerate digitalization in the energy sector. The system is designed to simulate electricity flows and support controllers in anticipating and preventing grid overloads before they occur. However, it's not only the governmental energy sector that will benefit from the increased use of digital twins. Companies in the space are already finding ways to capitalize on this technology.

For instance, Siemens Energy, which builds high-fidelity models of turbines and heat-recovery systems that simulate corrosion, wear, and flow changes to predict maintenance needs, estimates that improving predictive maintenance and reducing planned downtime by just 10% could save the global power sector around $1.7 billion a year.

Similarly, GE Vernova combines real-time telemetry with advanced modeling. This allows engineers to fine-tune turbine performance for improved efficiency and reliability. GE's PowerUp software, for instance, has helped wind farms boost annual energy production by up to 5% under favorable conditions.

These examples demonstrate how predictive modeling with digital twins is revolutionizing the way power systems are maintained and optimized, making the goal of reliability a tangible outcome.

Infrastructure That Sees Trouble Coming

Public infrastructure is poised to benefit from digital twins, with promising pilot and research phases underway. One such example is Dr. Aaron Costin's bridge twin.

Dr. Costin of the University of Florida has merged sensor readings, weather data, and traffic loads within an AI-based digital twin model that helps predict bridge deterioration and improve infrastructure monitoring. He said, “We are moving toward a digital infrastructure where everything could be a digital twin. Whether it’s the entire UF campus or the roads around Gainesville, all of them could have pieces of data working together so you can monitor them for safety," Dr. Costin said on the University of Florida website.

Dr. Costin's model can detect subtle strain patterns in bridges that hint at future cracks and recommend reinforcement before visible damage occurs. Although this might not seem that important, repairing a bridge even a year earlier than planned can prevent countless accidents and save millions in costs, especially across thousands of structures.

However, it isn't only bridge systems in the infrastructure space that are seeing gains when using digital twins. The water and transport agencies are also experiencing similar achievements. For example, global databases of digital twin use cases, according to the Journal of the American Society of Civil Engineers list pipeline leak detection twins that reportedly allow targeted repairs and reduced wastage.

Ultimately, through the use of digital twins, existing infrastructure can be monitored more effectively, and new infrastructure can be planned more efficiently, saving time and money while maintaining public safety as a top priority.

Cities That Learn in Real Time

Cities are being turned into living simulations with digital twins that learn and adapt for the betterment of those who live and work within them. According to the American Planning Association, predictive simulation helps manage change before it occurs. This guides its outcome and ensures safety.

As the American Planning Association's Planning magazine explains, smart city digital twins allow planners to "explore new solutions to urban problems and improve planning activities such as public engagement and zoning, all in a controlled environment that mimics the real city".

A key example of this in action is Singapore's Virtual Singapore. The country has its own national-scale 3D model known as ‘Virtual Singapore.’ This model utilizes a digital twin to integrate data on buildings, environment, mobility, and infrastructure. With these integrations, planners can test various scenarios and explore different options. For example, flood response strategies, transport expansions, and emergency exercise scenarios are used to model crowd movements and identify bottlenecks before they occur.

However, it isn't only Singapore that is leaning into the use of this technology. Orlando, Florida, is another metropolitan area using a digital twin model. According to the Orlando Economic Partnership, Orlando's regional digital twin spans approximately 800 square miles, encompassing 40 square miles in high fidelity, and is utilized to analyze traffic congestion, infrastructure planning, and economic development scenarios, helping the city prepare for future growth.

Similarly, Shanghai is building an urban-scale digital twin in partnership with 51WORLD and Shanghai Shentie. This system will model the city's rail network in real time. It is believed that the new system will allow operators to visualize passenger flow, simulate emergencies, and improve scheduling to reduce unnecessary congestion.

It's clear to see that each experiment in the virtual world informs tangible improvements in the real one, demonstrating the growing importance of digital twins in urban planning and management.

Medicine That Anticipates

For years, digital twins have been utilized in healthcare for research; now, these systems are entering the clinical use phase of their evolution. As Dr. John Halamka of the Mayo Clinic notes, their use is "no longer in the realm of science fiction".

This marks a turning point where static record-keeping is moving toward predictive modeling. This shift enables medicine to test interventions and outcomes virtually before they occur, which has monumental ramifications for patients.

One example of this is a 2024 real-world study conducted in India. This study encompassed 1,850 patients with type 2 diabetes. In the study, each participant's digital twin was modeled to reflect their glucose response. This offered real-time lifestyle guidance. After a year, with the help of the twins' insights, about 89% of participants achieved their targets, and the average HbA1c level dropped by 1.8 points.

Another example is provided by researchers at Oxford, Yale, and Johns Hopkins. A select group of researchers here is developing cardiac digital twins that integrate imaging, electrophysiology, and genetics to simulate heart performance under various therapies. Such models let physicians "rehearse" procedures virtually, reducing uncertainty and improving treatment precision for complex health conditions.

In the same vein of thinking, some ICU-based twins draw on real-time vital signs. These signs enable healthcare professionals to predict crises, such as sepsis, hours before they occur. MDedge believes this proactive capability could redefine critical care, enabling earlier, data-driven interventions.

With these discoveries in mind, and despite predictive healthcare still being in its infancy, the pattern is clear: physicians can utilize digital twins to anticipate what is likely to happen next, rather than just what has occurred.

The Responsibility of Prediction

Although there is no denying that digital twin advancements are the way of the future and beneficial to many industries, challenges arise with this technology.

One challenge is the somewhat over-dependency on data. Since digital twins rely heavily on data to make predictions, there is a possibility that faulty sensors or biased inputs can distort results, according to the U.S. Government Accountability Office. This is why human oversight and validation remain incredibly important.

Another challenge is interoperability. Bridge twins, power-grid twins, and city twins all rely on different standards. Unfortunately, without shared frameworks, experts have seen these systems struggle to interact and exchange information seamlessly. To counteract this, organizations such as NIST and ISO are developing protocols and standards to enable digital twins to share information more effectively.

Privacy and security, which are sensitive frontiers, especially in the United States, are also a concern. The US Government Accountability Office (GAO) has warned that issues such as data privacy, bias, and ownership could arise if digital twin information is misused. That's why strong encryption and transparent governance are essential to maintain public trust and keep individuals safe.

Access is another consideration. Not every company or organization has the computing power or specialized expertise needed to run high-fidelity twins. Fortunately, companies like Siemens, with its Siemens Xcelerator, and NVIDIA, with its Omniverse platform, are helping bridge this gap. These cloud-based ecosystems give smaller firms, hospitals, and cities the opportunity to build and test predictive models without the steep infrastructure costs typically required.

Lastly, there is the human dimension. Predictive twins shouldn't replace humans but rather complement expertise. Doctors, engineers, and planners must learn to interpret these models and understand their limitations. Used wisely, digital twins offer people the ability to act proactively before crises unfold; used carelessly, they risk creating new blind spots instead.

Looking Toward the Future

Digital twins clearly can further develop industries, providing incredible benefits, but they are not without their challenges. It is up to industries, organizations, and governments to determine how best to utilize this ever-evolving technology to benefit advancements within their respective fields and the broader global community. It is also up to these same players to navigate the inherent challenges that come with using these systems.