Vention Launches Generalized Physical AI Pipeline for Factory Robots

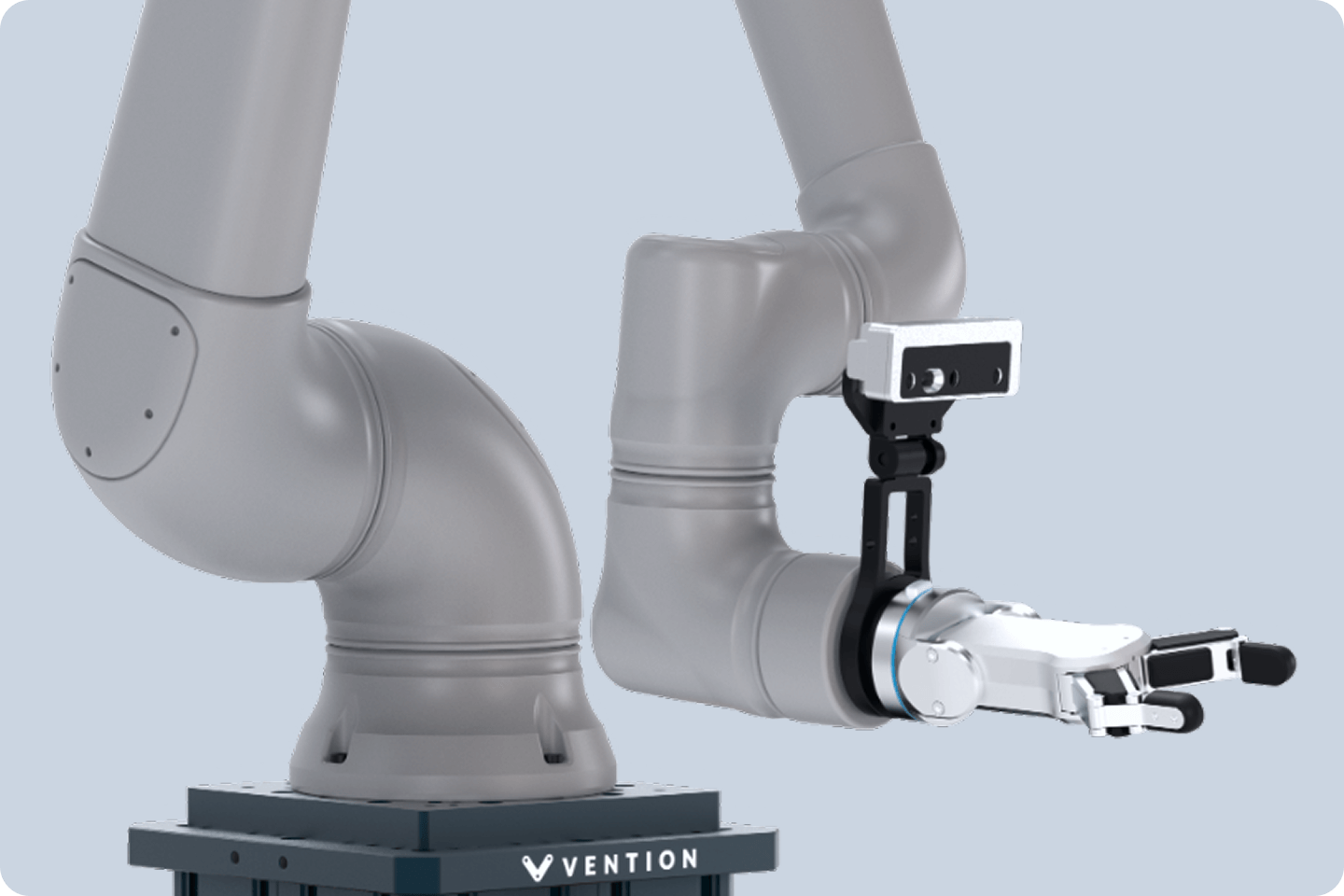

- Vention introduced GRIIP, an end-to-end physical AI pipeline designed to deploy autonomous robot cells in unstructured manufacturing environments.

- The system sustained 24/7 lights-out production for three months, maintaining throughput of up to five parts per minute without performance degradation.

Vention is stepping beyond task-specific robotics with the launch of GRIIP (Generalized Robotic Industrial Intelligence Pipeline), a unified physical AI system for manufacturing automation. The goal is to replace fragmented, one-off robot programming with a single scalable pipeline that can run across different factory workflows.

GRIIP is built to run autonomous robot cells in factory environments that aren’t perfectly structured or pre-programmed. Instead of stitching together separate vision and motion systems, it brings the entire process, from seeing a part to moving it, into one pipeline. The system combines Vention’s proprietary models with NVIDIA Isaac open models to manage scene digitalization, object detection and segmentation, 6DOF pose estimation, grasp evaluation, and collision-free path planning. It works without training data, allows CAD-to-pick setup in 15 minutes, and supports full deployment in under two days.

Vention says GRIIP can be deployed across common factory tasks, including bin picking, machine tending, conveyor pick-and-place, kitting, depalletizing, and sanding, using the same underlying system rather than task-specific programming. The company reports sub-millimeter pose estimation accuracy and sustained cycle times of up to five parts per minute during three months of continuous lights-out production, with no performance degradation.

With over 25,000 machines deployed worldwide and a community of more than 4,000 factories, Vention says GRIIP can convert existing traditionally programmed robotic applications to autonomous operations and provide a clear upgrade path for automation infrastructure.

🌀 Tom’s Take:

Less custom engineering, more out-of-the-box autonomy. If GRIIP delivers, it shifts robotics from carefully programmed tasks to production cells that can adapt and keep running.

Source: PR Newswire / Vention