Sharpa’s New VTLA Model Targets the Hardest Problem in Robotics

- Sharpa introduced CraftNet, a VTLA model that combines vision, tactile sensing, language, and action for fine robotic manipulation.

- The company frames CraftNet as central to its mission of “manufacturing time by making robots useful.”

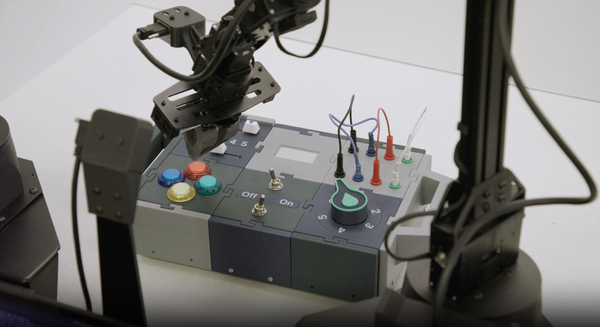

Sharpa has introduced CraftNet, a control system for fine robotic manipulation that combines vision, tactile sensing, language, and action, which the company calls VTLA. The system is built to run on real robots and carry out long physical tasks without scripting or simulation. Sharpa links CraftNet to its core mission: “We manufacture time by making robots useful.”

CraftNet is built on Sharpa’s multi-system architecture, designed to mirror how humans combine reflexes with higher-level planning. It includes two layers: System 0, the Interaction Brain, handles fast, reflex-like responses, while System 1, the Motion Brain, manages longer-term coordination. Sharpa says this structure enables reliable control at the “last millimeter”, a challenge it describes as “90% of the problem” in fine manipulation.

The company points to opportunities in retail, restaurants, hotels, and eventually the home, where robots could move beyond novelty and take on real tasks. Each job handed off to a robot becomes, in their words, a deposit into humanity’s “time bank.”

🌀 Tom’s Take:

Dexterity is still the hardest problem in robotics, and CraftNet is Sharpa’s attempt to solve it with a system built for real-world control.

Source: PR Newswire / Sharpa