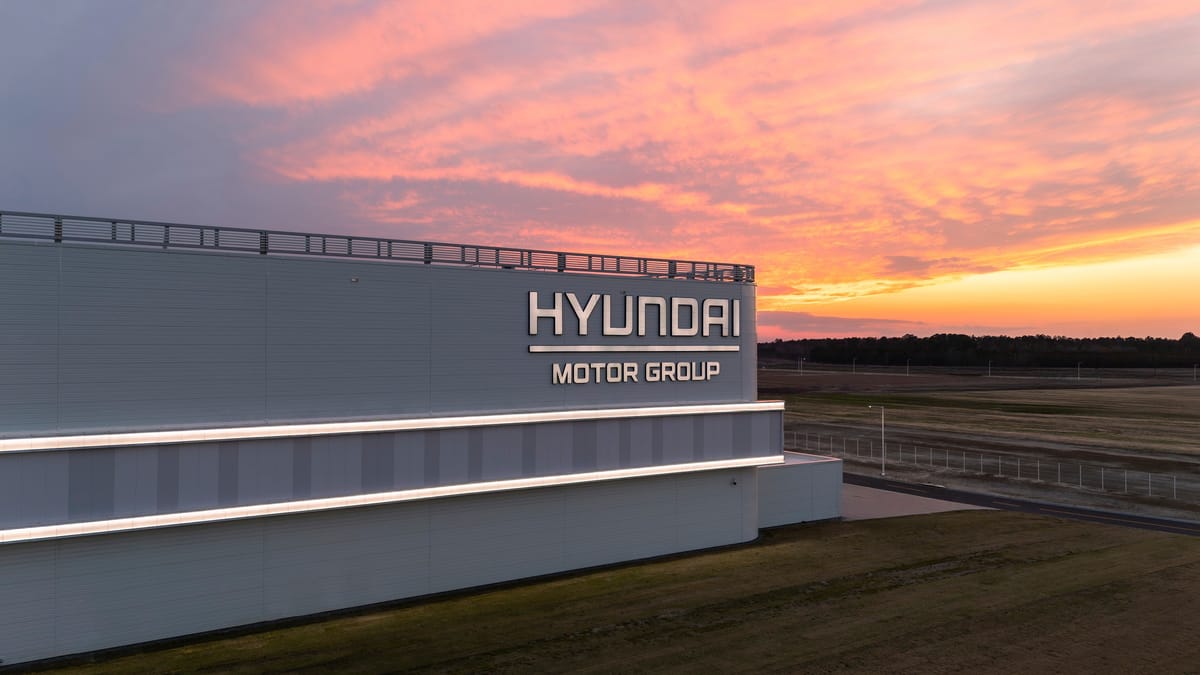

Hyundai’s U.S. Metaplant Launches with Fleet of Factory Robots and Smart Automation

- New Georgia-based factory features integrated AI, robotics, and autonomous drones across manufacturing and logistics.

- Boston Dynamics’ All-New Atlas humanoid robot to pilot as part of human-robot collaboration initiative.

Hyundai Motor Group has opened its $12.6 billion Metaplant America in Ellabell, Georgia — its most advanced smart factory to date. The facility, part of Hyundai’s vision for “human-centered” manufacturing, is a Software Defined Factory (SDF) integrating AI, robotics, and real-time logistics automation.

Autonomous mobile robots (AMRs) navigate the floor to manage inventory and parts delivery. Drones powered by AI continuously monitor stock levels and forecast needs, enabling just-in-time supply chains. The plant also features a fully connected production line where order collection, procurement, and assembly are digitally orchestrated.

As part of the next phase of its human-robot collaboration strategy, Hyundai will pilot Boston Dynamics’ newly upgraded All-New Atlas humanoid robot at the plant — exploring how bipedal robotics can support workers in real-world manufacturing environments.

🌀 Remix Reality Take:

This isn’t just a car plant — it’s a testbed for the future of factory intelligence. From drones to humanoids, Hyundai is quietly turning industrial robots into coworkers, not just machines.

Source: Hyundai Motor Group