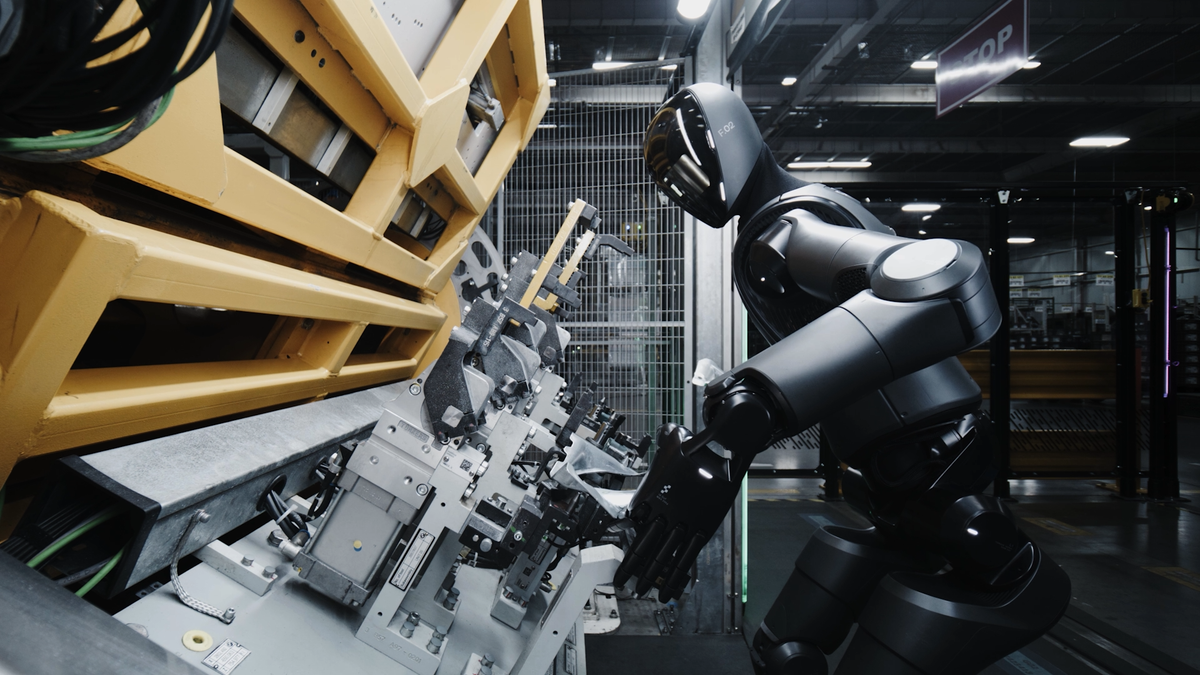

Figure’s Humanoid Robot Supports Production of 30,000 BMW Vehicles

- Figure 02 ran daily shifts at BMW’s Spartanburg plant, loading over 90,000 parts as part of a live assembly line deployment.

- The company shared deployment metrics—such as 1.2 million steps and over 30,000 vehicles supported—which informed mechanical updates in Figure 03.

Figure has published a report detailing the results of an 11-month deployment of its second-generation humanoid robot, Figure 02, at BMW Group Plant Spartanburg. After six months of setup and testing, the robot was integrated into a live automotive production line, running 10-hour shifts from Monday to Friday. During that time, it loaded more than 90,000 sheet-metal parts and supported the assembly of over 30,000 BMW X3 vehicles, logging approximately 1.2 million steps across more than 200 miles.

The robot’s task was to place sheet-metal components onto a weld fixture with a 5-millimeter tolerance. Performance was measured using cycle time, placement accuracy, and human intervention rates. With a load-time target of 37 seconds, a goal of 99% placement accuracy, and a human intervention target of zero per shift, the deployment focused on balancing speed and precision during live production shifts, according to the company.

Source: Figure

Figure says that insights from over 1,250 operational hours were used to guide the development of its latest generation robot, Figure 03. Data from the deployment informed mechanical updates in Figure 03, including a redesign of the wrist system to remove the distribution board and dynamic cabling, reducing complexity and improving reliability.

🌀 Tom’s Take:

For all the hype around humanoid robots, this report delivers hard numbers: 1,250+ hours, 90,000+ parts, 30,000+ vehicles. This is not a demo. It is a validation on the line.

Source: Figure