DEEP Robotics Deploys Dual-Robot System for Smarter Tunnel Inspections

- DEEP Robotics has launched a collaborative inspection system that links two existing robots for continuous monitoring of power tunnels.

- The combined platform enables 6–8 hours of autonomous operation with real-time cloud-based fault detection.

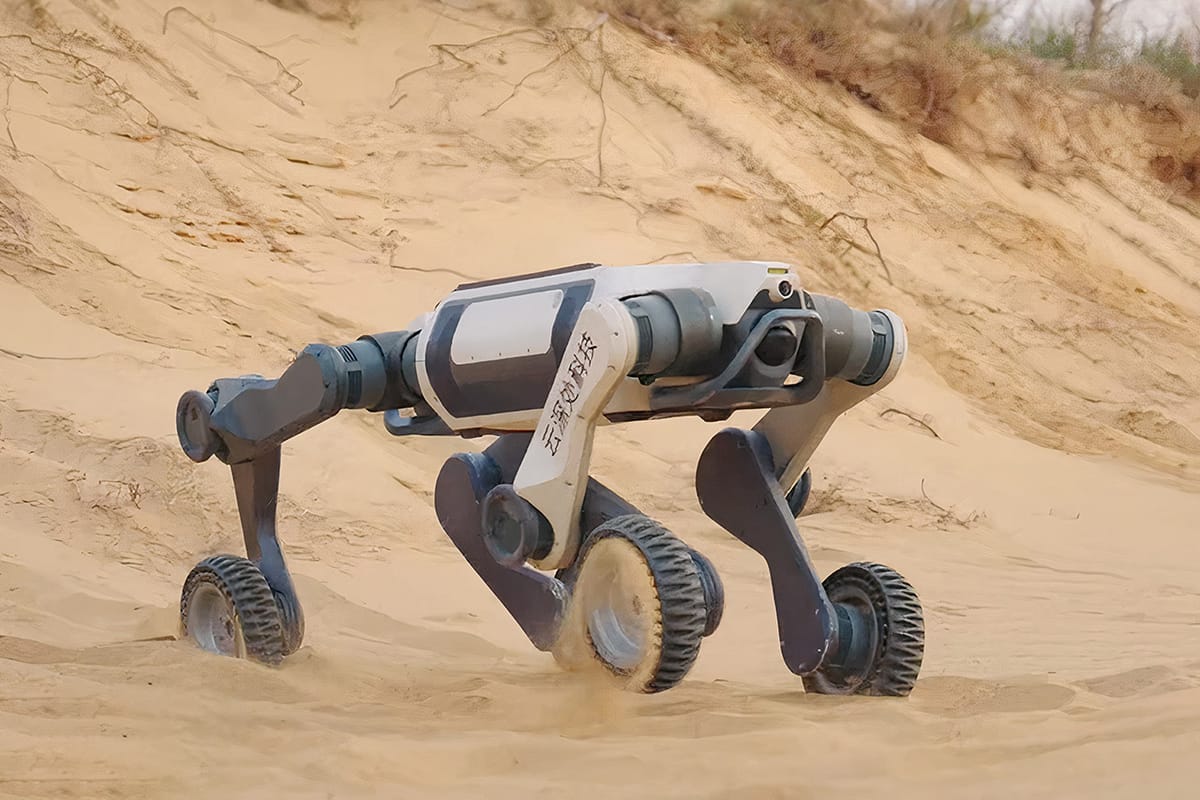

DEEP Robotics has introduced a multi-robot system that coordinates the Jueying X30 and LYNX M20 robots for intelligent tunnel inspections. The deployment marks a new operational model, combining complementary capabilities into a single automated solution for the power sector.

The Jueying X30, a quadruped robot, navigates complex routes while using sensors and a robotic arm to detect hazards. The LYNX M20 uses a wheel-legged design for high-speed patrols, scanning for temperature anomalies. Working in tandem, they operate autonomously for 6–8 hours, delivering full corridor coverage every two hours.

Data from both robots is fed into a cloud platform for real-time analysis. Built for harsh conditions, the system aims to cut inspection time, reduce risk to personnel, and improve infrastructure reliability. Currently deployed in Zhejiang, China, the system is positioned for future rollout in international markets.

🌀 Tom’s Take:

DEEP Robotics is now operating the Jueying X30 and LYNX M20 as a combined system for tunnel inspections, not just as individual robots.

Source: ACCESS Newswire / DEEP Robotics