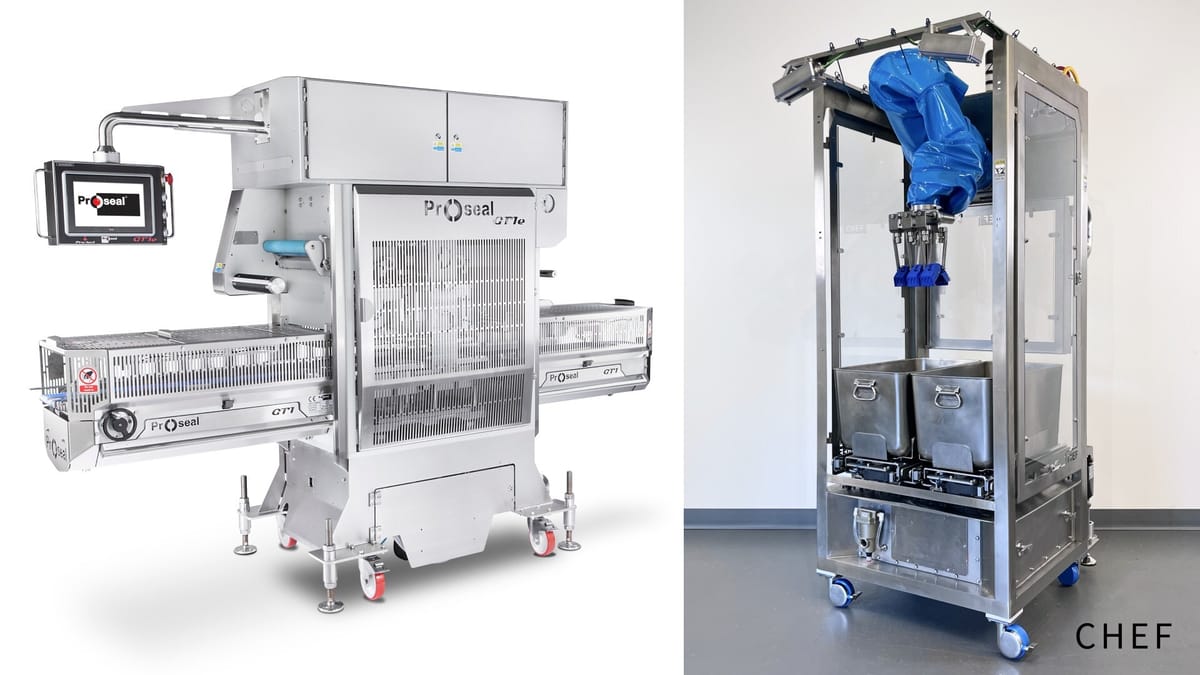

Chef Robotics and Proseal Partner on Flexible Meal Line Automation

- Chef Robotics and Proseal have partnered on a flexible system that automates both meal assembly and packaging for fresh and frozen foods.

- The solution supports high-mix production with fast changeovers, helping food manufacturers handle more SKUs with less labor.

Chef Robotics and Proseal have teamed up on a flexible automation system that assembles and packages fresh and frozen meals. Designed for high-mix production, it handles a wide range of SKUs with quick changeovers, making it easier to produce different ready-to-eat and ready-to-cook meals on the same line.

"Food companies are under more pressure than ever to reduce costs and increase throughput while maintaining flexibility," said Rajat Bhageria, CEO of Chef Robotics, in a press release. "By partnering with Proseal, we can deliver a seamless automation solution that goes beyond meal assembly to include sealing and packaging. Food manufacturers with high-mix, high-volume production environments can now handle food assembly and packaging with the same precision and flexibility at a fraction of the labor cost."

The system combines Chef’s vision-guided robots with Proseal’s high-speed sealing machines. It fits easily into existing lines, runs safely next to staff, and helps free up workers for more valuable tasks without slowing production.

The solution is now available to food producers in the U.S. and Canada. Chef Robotics is the first company to commercialize a scalable AI-powered food robotics system, with more than 65 million meals produced using its platform.

Source: YouTube / Chef Robotics

🌀 Tom’s Take:

High-mix food production needs robots that can keep up, switching tasks fast, handling different ingredients, and staying flexible without stopping the line. This partnership shows AI and modular automation are finally catching up to that reality.

Source: PR Newswire / Chef Robotics