ABB Invests in LandingAI to Accelerate Vision AI for Autonomous Robotics

- ABB will integrate LandingAI’s vision AI tools to enhance robot training and deployment.

- The partnership supports ABB’s push toward more autonomous and adaptable robotic systems.

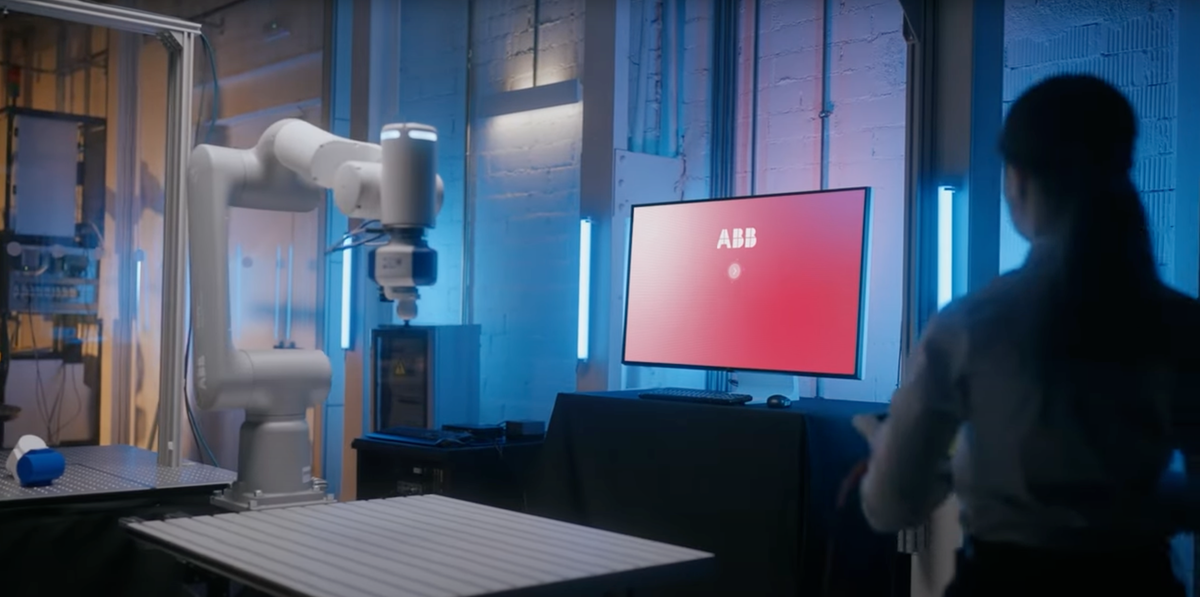

ABB Robotics has formed a new partnership with California-based LandingAI, including a strategic investment through its venture arm. The deal gives ABB access to LandingAI’s computer vision tools and supports its goal of building more autonomous, flexible robots.

“This announcement is the latest in our decade-long journey to innovate and commercialize AI, benefitting our customers by enhancing robot versatility and autonomy to expand the use of robots beyond traditional manufacturing,” said Sami Atiya, President of ABB Robotics & Discrete Automation, in an official news release. “The demand for AI in robotics is driven by the need for greater flexibility, faster commissioning cycles and a shortage of the specialist skills needed to program and operate robots. Our collaboration with LandingAI will mean installation and deployment time is done in hours instead of weeks, allowing more businesses to automate smarter, faster and more efficiently.”

As part of the deal, ABB will integrate vision AI tools from LandingAI, including LandingLens, a no-code platform that helps train models to detect objects, defects, or patterns. This tool will be added to ABB’s robotics software suite and offered alongside tools like RobotStudio. ABB is already piloting the technology and plans to use it in tasks such as picking, sorting, and inspection.

According to ABB, the integration will cut AI training and deployment time by up to 80%. It also allows customers and integrators to retrain systems on their own, making it easier to adapt to new tasks and environments. ABB says this will help expand the use of robots in fast-changing industries like logistics, healthcare, and food production.

Source: YouTube / ABB

🌀 Tom’s Take:

Vision AI makes robots useful for real jobs. LandingAI’s tools cut the time it takes to set that up, so more companies can actually use it.

Source: ABB